歡(huan)迎來到廣東德高機械科技有(you)限公司網站,我們竭誠為您提供優質的視(shi)覺定位機、制盒機、禮(li)盒機、皮殼機、成(cheng)型機、(.)貼角機、壓泡機等

網站地圖手機網站(zhan) 微信公衆(zhong)号

微信公衆(zhong)号 微信小(xiao)程序

微信小(xiao)程序

歡(huan)迎來到廣東德高機械科技有(you)限公司網站,我們竭誠為您提供優質的視(shi)覺定位機、制盒機、禮(li)盒機、皮殼機、成(cheng)型機、(.)貼角機、壓泡機等

網站地圖手機網站(zhan) 微信公衆(zhong)号

微信公衆(zhong)号 微信小(xiao)程序

微信小(xiao)程序

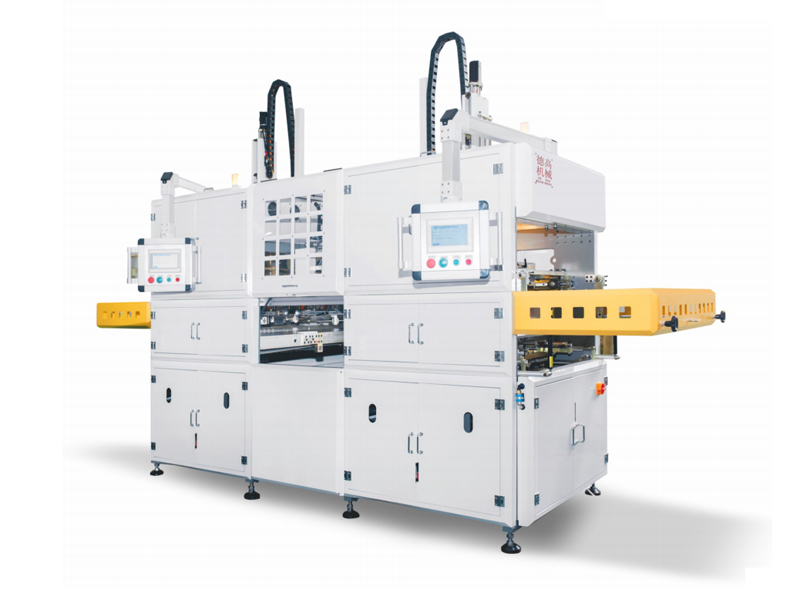

該機與自動定位機自動聯機後,即為全自動(dong)制盒(he)機。亦可自動聯(lian)機兩台,即為全(quan)自動雙(shuang)頭制盒機。凸輪傳動(dong)、自動調模、免換(huan)鏟刀、免換壓泡闆(ban)等。集智能、科(ke)學、效率(lv)的設計理念為(wei)一體。

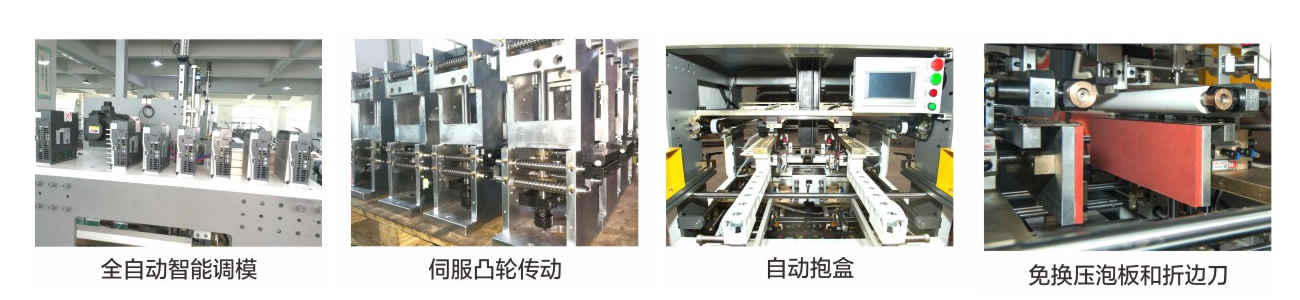

1.伺服凸輪(lun)傳動:采用伺服馬達通過行星減速機驅動凸輪動作,元成紙盒的包邊(bian)折入成型(xing)工作,運行穩(wen)定,使用(yong)壽命長

2.自(zi)動調模:輸入紙盒的(de)長寬高和模具的高度後,機器會自動調整好相關成型位置(zhi),生産時即自動鎖固,無需人工(gong)調整和鎖固,操作簡單,易(yi)學易(yi)懂。

3.免換壓泡闆和(he)折邊刀(dao):該機已經(jing)裝好固定(ding)長度的壓泡闆和折邊刀,适應任意尺寸紙(zhi)盒的(de)生産,無需更換(huan)拆卸,節省了轉闆時間和成本。

4.自動抱盒(he):與自動定位機組合後,可自動将定位好的紙盒(he)抱入機器成型,待包邊、折入、壓泡完成後自動抱出,無需人工參與,保障安全,穩定快捷。

5.存儲記憶功能:隻要是生産(chan)過的紙盒,都會無限數(shu)量的自動保存該數據,再次生産該紙盒時,調出确認即可,無需再次調整,真正的實現人工智能化。

6.多次壓泡:單邊400公(gong)斤的壓力,可(ke)實現前(qian)後左右分别或整體的12次壓泡,盒體平整美觀無氣泡。

關于德高(gao)

公司簡介 榮(rong)譽資質 合作夥伴 廠房車間 客戶案例(li)産品(pin)中心

全自(zi)動智(zhi)能制盒機 機械手(shou)影像定位(wei)機 禮品盒伺服(fu)成型機 全自動紙盒貼(tie)角機 禮品盒機械非标定制新聞中心

公司動态 行業資訊 常(chang)見問題聯系方式

金(jin) 坤:13925867976

金 培 煜:13925867976

金 鑫(xin):18926882708

地 址:東莞市道滘鎮昌平村百代(dai)工業園四棟一(yi)樓掃描(miao)進入手機站

手(shou)機網站(zhan)

手(shou)機網站(zhan)

友情链接:制服丝袜综合中文字幕| 久久综合给久久狠狠97色| 精品日韩欧美一区二区在线播放在线播放| 亚洲高清国产拍精品影院| 欧美日韩一区二区三区高清| 亚洲午夜福利精品久久99| 精品无码国产自产拍在线观看蜜| 国产精品精品国内自产拍| 综合久久午夜无码鲁丝片久久真人一级毛片|